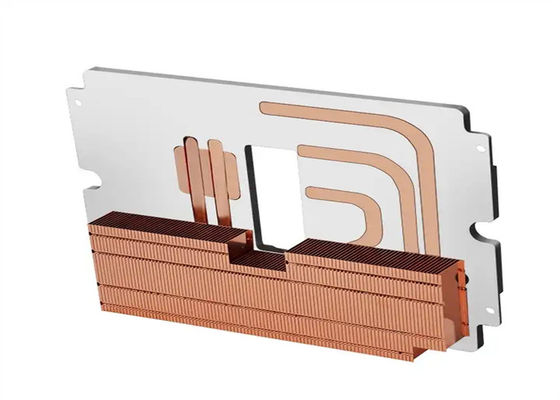

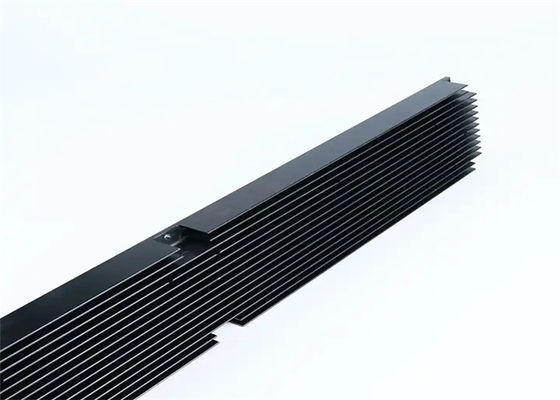

5G Base Station Heat Sink & High-Speed Rail Bogie Die Cast Components

Core Product Positioning

This series of precision die castings utilizes advanced high-pressure die casting technology with core advantages of lightweight design, integrated structure, and high reliability. Through material innovation and process optimization, we provide integrated structural solutions for high-end manufacturing fields including automotive, high-speed rail, electronic communications, and aerospace. Our capabilities range from micro electronic heat sinks to extra-large automotive body structural parts, enabling one-time molding of complex shapes to significantly improve end product performance and manufacturing efficiency.

Core Performance and Process Advantages

Ultimate Lightweight and High Strength

- Material Matrix: Lightweight alloys including aluminum alloys (Series 380, 413) and magnesium alloys (AZ91D, AM60), achieving 30%-50% weight reduction compared to traditional steel components. Magnesium alloy die castings provide an additional 20% weight reduction.

- Structural Strength: High-vacuum die casting process maintains porosity below 1%. Combined with insert die casting technology, component fatigue life increases 3-5 times, meeting requirements for high-frequency vibration applications like high-speed rail bogies and automotive chassis.

Precision Molding and Integration Capability

- Precision Control: Achieves dimensional accuracy of ±0.1mm and thin-wall molding capability down to 0.5mm, ideal for precision structures in 5G base station heat sinks and mobile phone frames.

- Integrated Manufacturing: Supports extra-large integrated die casting, consolidating 70+ parts into single components (e.g., Tesla Model Y rear floor), reducing welding points by 90% and significantly improving structural stability.

Efficient Adaptability and Customization

- Process Adaptability: Covers 7 major process types including hot-chamber die casting (small zinc alloy parts), cold-chamber die casting (large aluminum alloy parts), and vacuum die casting (high-strength parts), with customizable production processes.

- Surface Treatment: Supports anodizing, powder coating, electroplating, and functional properties including corrosion resistance (EN 45545 fire protection standard), electromagnetic shielding, and thermal conductivity.

Full-Scenario Application Solutions

Automotive Industry

Integrated body structural parts and battery casings provide new energy vehicles with 10%+ increased range while improving production efficiency by 40%, effectively balancing performance and manufacturing costs.

High-Speed Rail Equipment

Bogie gearboxes and braking system components with excellent anti-vibration fatigue performance meet strict operational reliability requirements for long-term stable operation.

Electronic Communications

5G base station heat sinks and mobile phone frames with thin-wall heat dissipation design and lightweight characteristics address miniaturization and efficient heat dissipation needs.

Aerospace

UAV casings and satellite brackets using magnesium alloy materials achieve optimal balance between lightweight design and structural rigidity, meeting strict aerospace weight and performance standards.

Consumer Goods

Wearable device casings and sanitary hardware with water/stain resistance properties ensure portability and durability for enhanced consumer product experience.

Quality Assurance and Technological Innovation

- Full-Process Quality Control: MAGMA simulation software optimizes mold design, reducing test molds by 30%. AI monitors pressure and temperature parameters in real-time for batch consistency.

- Green Manufacturing: Achieves 95%+ waste recycling. Cold-chamber die casting machines save 30% energy, complying with low-carbon production standards.

- Technological Upgrading: Deploys multi-material composite die casting (carbon fiber reinforcement, 3D printing inserts) and expands high-performance materials like titanium alloys.

Core Product Value

We provide full-chain services from material selection to after-sales technical support. Our structural integration solutions reduce end product weight and manufacturing costs while advancing high-end equipment toward lightweight and intelligent development through material and process innovation.

Material Specifications

Aluminium Alloys

Highly corrosion-resistant aluminum alloys ideal for die-cast parts exposed to environmental elements:

- Aluminium 46100 / ADC12 / A383 / Al-Si11Cu3

- Aluminium 46500 / A380 / Al-Si8Cu3

Magnesium Alloys

High strength-to-weight ratio magnesium alloys with excellent corrosion and wear resistance:

Zinc Alloys

Excellent heat and electricity conductors for parts requiring rapid heating/cooling.

Industry Applications

- Automotive: Engine blocks, cylinder heads, transmission cases

- Electrical: Switchgear, panel boards, circuit breakers

- Aerospace: Aircraft and spacecraft components

- Appliance: Components for various appliances

- Furniture: Hardware including drawer pulls and knobs

- Other Industries: Medical, construction, and toy manufacturing

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!